Posted On: Saturday - December 2nd 2023 9:23AM MST

In Topics: Science Inflation

This post is a follow-up to both Thursday's Inflation by Deflation - building materials Part 2 x 2 and our 5 y/o post Inflation by Deflation - building materials version. Why is it "2.2" in the title? We're still talking wooden 2 x 2's [sic] here, but, (call it) the 2nd, "2" is now on its 3rd iteration from my adult recollection of dimensions, 1.5" to 1.4" to, now 1.3125" (1 5/16"). (You too may be wondering about the 1.4", which is not a round English unit value. Perhaps it's off by a slight amount, but it wouldn't be much.)

OK, if I'm going to get into structures a bit, I have to put down a number of caveats here. These slides I found have "formulae" for 3 types of loading. Please realize that there is indeed a lot more to it. A non-Engineer who figures "I can design an experimental airplane because I have a copy of this Finite Element Analysis software" is not necessarily the guy to ride along with on the first test flight. There is much more too it, and blindly following analysis software or formulae without knowing more of the theory usually gives bad numbers.

Firstly, no, 1 x 2's and 2 x 2's are not considered residential structural lumber, as was argued to me in comments on The Unz Review. I get that, but that doesn't mean I haven't used it as such. The table top I mentioned had both types in it, and the idea was to support things. That's structural. Many other uses may be structural. Mostly, sure, these are "furring" strips, used for spacing and attachment* of siding or whatever - even that spacing difference screws things up for us though. For the 2 x 2's, since 2 of them don't match up to a 2 x 4, their use around window framing or whatever may be precluded.

Secondly, regarding the engineering calculations, when it comes to using wood (or anything) structurally, usually we're talking about a more complicated arrangement. 2 x 4's are spaced inside sheetrock as a wall, and columns are made of multiple pieces and all that. Still the basic strength differences, new v old, hold when we go from the simple case to the complicated, i.e. real, application.

Thirdly, I've been writing "strength", but it's not the theoretically precise way to discuss structures, just as, well, good luck getting a mechanic to say "36 psi" is your tire pressure rather than the colloquial "36 pounds". What follows is the same as the footnote in that old 1 x 2 post. This is in regard to discussion of bending, but it applies generally:

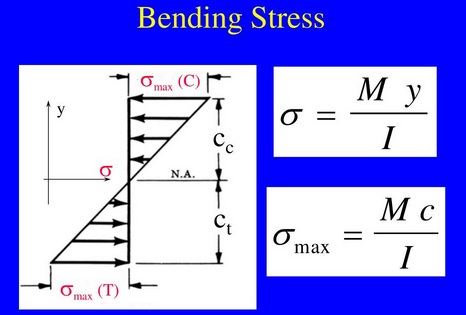

Technically, the highest stress in the wood in bending occurs at the outside, it's this stress that goes up inversely with the square of thickness (linear with the other dimension, BTW). We should think of the strength of the material as a property of the stuff, whether, in this case, say yellow pine or poplar. We end up with higher stress in the same strength material which means colloquially "lower strength".Finally, these calculation are based on homogeneous, isotropic materials. The first means material with even properties throughout, and the second (this IS different) means that these properties are equal along all three directions. Well, guess what, wood is neither. As far as homogeneity, on the scale we're using it, it's just a matter of knots and such that make it non-homogeneous. That's part of what safety factors are for. Wood is most certainly NON-isotropic, but these kinds of loading will have the grain direction as the important one. Therefore, we can get a fairly decent number for strength of yellow pine, poplar, whatever it is and a somewhat decent number for that "E" (Modulus of Elasticity, the inherent stiffness of the material) used in the buckling formula.

I'm sorry that ALL THAT had to be said before I get started. Were I knot to (typo intended), it would be fair for someone to give me grief about that. Also, in the calculations below, keep in mind that I'm not taking material strength of the wood itself - see Adam Smith's link under the recent post, as that has gone down too. Let's hold that all equal as the same quick-growth lumber, which IS probably the case from the 1990s on. When I write "strength" here, I really mean the ability to hold a certain loading with a certain geometry vs using the older and bigger material.

Now, for the fun part:

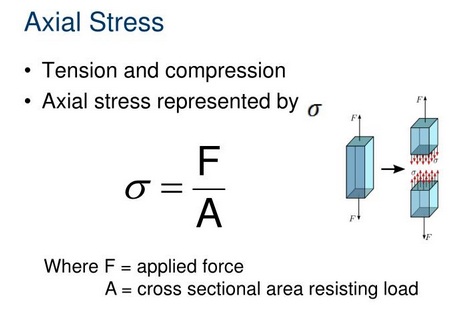

Axial loading, whether compression (with a caveat to check for buckling) or tension is very simple. Stresses are the same throughout the cross-section. The simple "normal" (away from or into the surface) are F/A.

Simple, so let's do this. That X-sectional area of these 2 x 2's has gone from 2.25 in2 in the '90s (call them size "A") to 1.96 in2 at least 5 years back (B) to 1.72 in2 recently (C). Therefore, in axial loading, buckling (of long pieces in compression) excluded for now, B pieces are 87% of the strength of A's, while C pieces are only 77% as strong. Now, if we compare to that mythical(?) ACTUAL 2" x 2" cross-section, we get a reduction to 56% axial loading strength A's, to 49% for B's, and to 43% for the newest, the C's.

There is quite a bit to analysis of bending, not least the loading itself, which comes in in that "M", the bending Moment. Some may prefer to think of a torque, but torque is usually thought of about an (almost always) round axis. Moment is more general. That "moment" is not to be confused with the name for the capital "I' terms. That is Moment of Inertia, which is a geometric property of the cross-section. There's a nice little piece of Calculus behind it, but for a rectangle, I is 1/12 bh3. Wait, which side is "b", the base, you ask, and which is "h", the height"? "b" is the side parallel to the axis about which the beam is being bent. For most uses of 2 x 4's in bending, for obvious reasons, b is the short side, the 1.5". (Note which "b" v "h" gives the higher I.) I wrote that for the general rectangular case, but then we have a square here. I = 1/12 x actual dimension4.

That "c" is the distance to the outer "fiber" (they call it), where the highest normal stress is produced. (It's 0 at the centerline.) For this simple rectangular cross-section, c = h/2.

All other things equal besides our having gotten cheated out of material year by year, the bending stress, hence the reduction in strength, goes inversely with the base (b), and inversely with the square of the height (h), of the cross-section. (Note that I goes as the cube of h, but then c, hence h, appears again in the numerator of the formula.) For a square, then, strength of the structure very simply goes down inversely with b3.

Let's do the calculation for bending normal stress for the 3 square cross-sections. B's have 81% of the bending strength of A's, and C's have 67% of that of A's. Starting from that old mythical wood straight outta Sherwood Forest, we get reductions to 42%, to 34%, and to 28% for A's, B's, and C's, respectively.

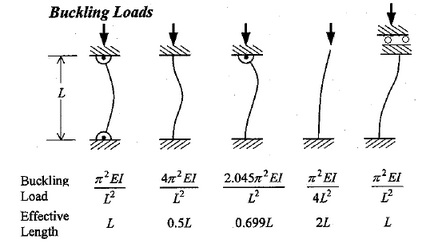

As a type of loading, buckling is really an odd duck. If you note the formulae, stress in the material, to be compared with its inherent strength, is not in there. That's because buckling is a phenomenon of instability not strength. At a certain critical loading of a column, any slight offset of the load from the centroidal axis** results in bending, but generally columns don't "do" bending. The more the bending deformation (deflection), the higher the offset becomes, increasing the bending moment more, an unstable situation that's really not good for anybody. (Ha, but, there's a lot more to this also. The end "conditions" - how the column is attached to the other structure - are important, as we see in our nice graphic.)

There's that Moment of Inertia for the cross-section again. That's where the changed dimensions come in. Same thing, I = 1/12 bh3 = 1/12 b4 for this square cross-section.

For other things equal, the end conditions, that material property, E for the type of wood, etc, we'll do this buckling load comparison. In this case, I really shouldn't use the word "strength" at all. I'll just refer to how much that critical buckling load - the max limit - is reduced.

Critical load for buckling for B's is 76% of that for A, and for C's it is down to 57%. As compared to the 2 x 2's used in that old mead lodge, we're talking 31%, 24%, and 19% for A's, B's, and C's, respectively.

That's a lot of numbers, so I may make a nice table elsewhere, take a screenshot, and put that in another post. Suffice it to say that, not only are we getting screwed by obvious huge price increases in lumber, but this cross-sectional-dimension version of inflation by deflation is bringing the strength of our wood down, meaning we need more to do the same job.

... and this was to be a short post. Ya' see what I mean?!

* Attaching siding or whatever to a narrower piece can reduce strength of the project too, depending on the application.

** This involves another Calculus-adjacent property of areas (the cross-section again, in this case), the Centroid. It's all cool stuff, IMO.

*******************************

[UPDATE 12/02 Eve:] Oops, I = 1/12 bh3. Had left out the 1/12, very important, of course to get the actual number, but it washes out in the comparisons anyway. [NOBODY CARES! - Ed.]

*******************************

Comments:

Moderator

Saturday - December 2nd 2023 7:06PM MST

PS: Ooops, I forgot to mention that no, I didn't get the premium lumber in that size. That would be something to consider indeed.

I'll check out your links. I've looked at those portable sawmills before - very enticing! I have a tree that might have to come down, not because it's a hazard, but for space. It'd be say, as it's a very nice straight Scarlet Oak, maybe 18" in diameter now at shoulder height. I would hate to just throw out that beautiful wood after killing the beautiful tree also.

I'll check out your links. I've looked at those portable sawmills before - very enticing! I have a tree that might have to come down, not because it's a hazard, but for space. It'd be say, as it's a very nice straight Scarlet Oak, maybe 18" in diameter now at shoulder height. I would hate to just throw out that beautiful wood after killing the beautiful tree also.

Moderator

Saturday - December 2nd 2023 7:03PM MST

PS: Note first, Adam, that just after you wrote I had to correct the Moment of Inertia for a rectangle formula. I'd left out the 1/12, very important, of course, were one doing calculations to find stresses, but it washes out in any of these comparison calculations.

Yes, I bought 16 footers for one job - it made sense for simplicity, as I didn't even need to cut them. However, also, I think that was the length that gave me the best deal in mass of wood per dollar too. They'd have been tough to carry in my truck (would have to have loaded concrete bags on the ends near the cab for balance. I had a bunch of stuff delivered anyway, so these were part of it - my friend has the discount contractor card (he's not officially a contractor), so free delivery AND 5% off was the deal.

I wrote up the story about the communication breakdown and incompetence on that end in a post (though the guy who called and came out with the truck was great).

https://www.peakstupidity.com/index.php?post=2508

"Special Needs Delivery" is the title. Hopefully, next time will go smoother.

Yes, I bought 16 footers for one job - it made sense for simplicity, as I didn't even need to cut them. However, also, I think that was the length that gave me the best deal in mass of wood per dollar too. They'd have been tough to carry in my truck (would have to have loaded concrete bags on the ends near the cab for balance. I had a bunch of stuff delivered anyway, so these were part of it - my friend has the discount contractor card (he's not officially a contractor), so free delivery AND 5% off was the deal.

I wrote up the story about the communication breakdown and incompetence on that end in a post (though the guy who called and came out with the truck was great).

https://www.peakstupidity.com/index.php?post=2508

"Special Needs Delivery" is the title. Hopefully, next time will go smoother.

Adam Smith

Saturday - December 2nd 2023 6:32PM MST

PS: Greetings, Mr. Moderator,

I can't wait for Dieter to chime in on this post...

Seems right up his alley. 🙂

All kidding aside, thanks for the engineering lesson.

(Not that I know much about this sort of thing, but...)

This is a good explanation of why you have to buy larger long length lumber (16' or 20' 2"x8"s or 2"x10"s) and cut it down to the size you like if you want better quality lumber. (Assuming your shopping a big box store like HomeDepot or Lowe's and not going to a lumber yard that deals in hardwoods and other specialty lumber.) (Also assuming your not building a house or doing some other large project where you could justify trucking in higher quality lumber in bulk.)

https://www.homedepot.com/p/2-in-x-8-in-x-20-ft-Prime-Lumber-648078/100036371

This trick works because long lengths tend to be premium lumber (with a premium price tag) and of higher quality because they have to be in order to get the longer lengths.

For example, instead of buying 10' 2x4s you could by 20' 2x8s and cut them down, assuming you have a proper table saw and a way to transport longer length lumber. This would give you a 2x4 that is actually 1-1/2 x 3-5/8 instead of the standard 1-1/2 x 3-1/2...

https://i.ibb.co/Pgf2N13/common-dimensional-lumber-sizes.jpg

Of course you could cut them down further to 2x2s or what ever you like. Depending on your project you may also like to use kiln dried lumber.

Or, if you have some wooded land you could get one of these...

https://woodlandmills.com/portable-sawmills

Some quick examples of specialty and/or hardwood lumber...

https://www.hardwoodweb.com/

https://www.troymill.com/

https://thomaslumberco.com/

https://cagspecialtywood.com/

Cheers! ☮️

I can't wait for Dieter to chime in on this post...

Seems right up his alley. 🙂

All kidding aside, thanks for the engineering lesson.

(Not that I know much about this sort of thing, but...)

This is a good explanation of why you have to buy larger long length lumber (16' or 20' 2"x8"s or 2"x10"s) and cut it down to the size you like if you want better quality lumber. (Assuming your shopping a big box store like HomeDepot or Lowe's and not going to a lumber yard that deals in hardwoods and other specialty lumber.) (Also assuming your not building a house or doing some other large project where you could justify trucking in higher quality lumber in bulk.)

https://www.homedepot.com/p/2-in-x-8-in-x-20-ft-Prime-Lumber-648078/100036371

This trick works because long lengths tend to be premium lumber (with a premium price tag) and of higher quality because they have to be in order to get the longer lengths.

For example, instead of buying 10' 2x4s you could by 20' 2x8s and cut them down, assuming you have a proper table saw and a way to transport longer length lumber. This would give you a 2x4 that is actually 1-1/2 x 3-5/8 instead of the standard 1-1/2 x 3-1/2...

https://i.ibb.co/Pgf2N13/common-dimensional-lumber-sizes.jpg

Of course you could cut them down further to 2x2s or what ever you like. Depending on your project you may also like to use kiln dried lumber.

Or, if you have some wooded land you could get one of these...

https://woodlandmills.com/portable-sawmills

Some quick examples of specialty and/or hardwood lumber...

https://www.hardwoodweb.com/

https://www.troymill.com/

https://thomaslumberco.com/

https://cagspecialtywood.com/

Cheers! ☮️

Yeah, the Moment of Inertia for a rectangle formula looked a bit off to me, but I didn't want to say anything 🙃...

Just kidding. I've already got a couple drinks in me and I'm sure I couldn't check your math without spending a few days (or weeks) doing some research and really wrapping my head around what you've presented in this post.

Portable sawmills are great! Not so portable sawmills are great too. There is a sawmill in the stackhouse at work. (Near where the goats were hanging out by the firewood.) It makes a lot of sense there as they have a couple hundred acres of trees (mostly hardwoods) and the equipment to move large trees to the mill for processing. It really hasn't been used in a while as there is a large pile of already milled lumber stacked up for projects not yet imagined. But it is really nice to have in such a place.

Fun fact!: The cabin I live in (and several of the others here on the mountain) was (were) built with lumber milled here on site on a portable sawmill.

About 30 years ago there was a tornado on the mountain that knocked down a bunch of trees. Instead of turning it into firewood, or hauling it off for pulp, our landlord hired a guy with a portable sawmill to come in and salvage much of what the tornado tried to destroy. He hired an other guy to design (and mostly) build these cabins. And naturally, he did much of the work himself as well as hire others to help with various parts of the projects.

It would be a shame to cut down a beautiful healthy tree but sometimes you gotta do what you gotta do. Perhaps you can rent a sawmill or hire someone who has one to help turn your beautiful scarlet oak into beautiful lumber if you should decide to take it down.(?)

Great wood doesn't grow on trees, you know...

☮️